Its history dates back to 1910, when two brothers, Aleksander and Jozef, founded a forge together at 3 Radwanska Street. After ten years of dynamic activity, the forge is transforming at the horse carriages repair plant and their individual manufacturer (1920). The Wroblewscy perform all stages of the carriage’s production from design to final form. By 1935, the plant already employs about 20 people and is a well-known manufacture in Lodz. All the carriage drivers in Lodz knew about the Wroblewskis.

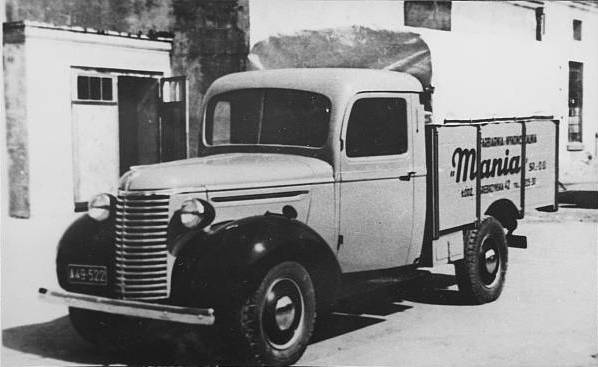

Along with the spread of motorization in Poland and changes taking place in transport, the Wroblewscy are deciding on a new form of production. In the new headquarters at 188 Wolczanska Street, where the plant is present, unit production of car body bodies is launched to this day (1935). On the frame with the engine and wheels made by Fiat or Chevrolet, the Wróblewscy assemble closed cargo bodies of vans. This is how the new truck brand “B-cia Wróblewscy” was created. The number of trucks produced to order was not very numerous and none has survived to the present day. Even before the transformation, Jozef goes to another business, and Aleksander and his sons Aleksander, Eugeniusz and Pawel continue the management of the “Bracia Wroblewscy” workshop.

From 1939, the company passed into the hands of the German Administration. The Wroblewskis are evicted, they leave Lodz, and at Wólczańska 188 the Wermacht repair service is activated. Germany is modernizing the workshop for its own needs but does not continue to produce trucks, focusing on ongoing repairs of the military fleet of vehicles stationed in Lodz. On the day of liberation, one of the few bombs that fell on Lodz destroys part of the plant. The Germans leaving the workshop left all the service equipment, apparently disassembly was not purposeful when escaping. The machine park was favored by Soviet soldiers who, with the permission of the authorities, took everything away as scrap metal.

The devastation of the facility contributed to the protection of the plant against nationalization – officials recognized that the facility has no value for the economy. The property remains with the Wroblewski family who decide to renovate it and continue operating in the form of a forge and car repair service.

Systemic difficulties in obtaining materials and parts for private property and the need to limit employment of employees effectively inhibit the restoration of splendor to a company from the pre-war period. The plant is divided into three craft units where Aleksander (father) ran a forge, one of his sons Eugeniusz dealt with mechanics and the other son Pawel – tin-work and varnishing. A sort of car repair center is being built at 188 Wolczanska. In 1969, father Alexander dies. His son Pawel takes over running the spring forge.

The Wroblewscy repeatedly faced the threat of another administrative expropriation, where the building at Wolczanska 188 was to be connected to the Lodz University of Technology or a telephone exchange. However, these plans were not implemented, thanks to which the plant retained its address.

In 1989 at the age of 68 Pawel Wroblewski dies at the time running the company together with his eldest son Michal. And a year later, his younger brother Stanislaw (current owner) joins the family business.

The political changes of the 90s towards opening up to imports from the Western market brought the company cooperation with Walker to produce exhaust systems. Brothers Wroblewscy then became the first and one of the few companies in Lodz to install dedicated exhaust systems. The dynamic development occurred in the years 1990 -1995 where the Wroblewscy as leaders in the assembly and sale of exhaust systems introduce the distribution of the first catalysts, followed by shock absorbers and other suspension components. Since 2000, the rivalry of large automotive spare parts distribution networks begins on the Lodz market. Under the pressure of foreign investment, the Wroblewscy company, forced from the market, is forced to limit sales and focuses on car service specializing in suspensions and exhaust systems. In 2011, one of the brothers dies – Michal. The company remains in the hands of Stanislaw.

When I was asking car mechanics, do they know which repair shop in Lodz is the oldest? – None of the respondents knew this. I found the Wroblewski family thanks to the Internet. A hundred-year tradition obliges – I thought, but on Wolczanska 188, apart from a fragment of the wooden building of the gate, I found nothing historical. The workshop looks quite average like most Lodz repair plants. Entering the property we will notice two offices. On the right is the workshop “Bracia Wroblewscy”, which consists of three employees and the owner Mr. Stanisław. On the left is his cousin Jacek, which took over the factory after Eugene’s father and specializes in ironing of bearings and sleeves.

Mr. Stanislaw in a calm voice told me the entire history of the company, while justifying its financial position. I quickly calculated that for 100 years of activity, half was a period of external factors devastating the company. I am referring to the period of the German occupation and later the occupation of the PRL Offices. It is not better today under fiscal occupation. Mr. Stanislaw has been observing the disappearance of customers demanding quality for those expecting cheap services for two years. The compromise sometimes conflicts with the brand’s philosophy. – There are parts that we prefer not to touch, says Mr. Wroblewski. Lack of warranty for a replacement is a risk of losing authority. In such circumstances, it is very difficult to meet the expectations of an economical customer.

What’s next? Mr. Stanislaw is wondering. Is there a threat that in a few years the indifference of customers will close the history of the oldest repair plant in Lodz? Lodz manufacturer of vans? It’s a bit annoying finale, or maybe it will happen before it is worth seeing this place and at least imagine how it could once looked in its pre-war glory? (Brux)

…………………………………………………

BRUXnews

RSS subscription: https://brux.news.blog/feed/

Editor contact: BRUXnews@post.com